Success stories and industry solutions

Every project begins with an idea. Whether it's individually implemented projects for our customers or industry-specific solutions, item is your reliable partner. Together, we develop the solution that brings you one step closer to your vision of tomorrow. Perfectly tailored to your requirements and conditions. Let yourself be inspired.

Success stories

Workplace design in repair services

Olympus took the expansion of its repair facility in Portugal as an opportunity to optimise the workplace design in the new building. Read here how Olympus Medical Products has increased employee well-being and efficiency as a result.

Cleanroom systems for highly sensitive manufacturing operations

When launching a new production line, SwissOptic created separate cleanroom-within-a-cleanroom systems. Based on item components, the solutions satisfy the most stringent demands in terms of cleanliness. Find out how these mini-environments can be flexibly adapted to a range of work processes.

Special closure meets smart conveying technology

KM Packaging GmbH utilises automated solutions to transport components and products from A to B in its production operations. Conveying technology from item plays its part by keeping processes efficient and workflows smooth. One particularly good example is the rotary indexing assembly system. This automated production process manufactures a special closure.

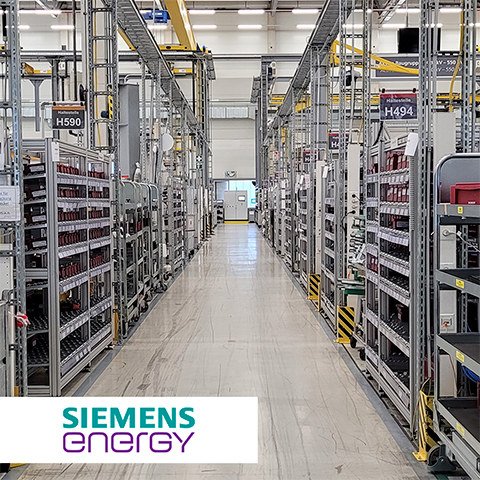

Flexibly kitted out with 2500 solutions

Component by component – Siemens Energy prioritises flexibility and modularity when fitting out its production workshops. This is why the company opted to use more than 2500 fixtures and fittings from item when redesigning its plant in Berlin.

Mobile robotics: Leading the way in intralogistics

Audi AG is famous for its innovative strength. For example, the Audi A8 is manufactured with assistance from mobile industrial robots, which convey supply trolleys based on our components to the production line on a fully automated basis.

Collaboration as a growth driver

CETPM and item – more than a decade of training in all things lean. When knowledge and practical experience go hand in hand – find out how our partnership with CETPM is making industry fit for the future. Read the success story here!

Automated welding for SMEs

INperfektion, Niederrhein Automation, and item are making it really straightforward for small and medium-sized enterprises to get started with automated production. The INNA robot cell features an impressive modular design, is intuitive to use and boasts outstanding flexibility, making it ideal for applications such as welding, grinding and bonding – even when working with small batch sizes. It all started with a very specific requirement from DAST Schweißtechnik GmbH.

Italian engineering meets XMS profiles

Customised automation and robotics solutions: Discover how Vensys uses XMS machine enclosures for two solutions in the automotive industry. It was above all the lightness, stability and aesthetic design that convinced them to choose item.

Efficient production logistics in automotive manufacturing

Learn how Toyota Motor Manufacturing Czech Republic (formerly TPCA) optimised its intralogistics with Karakuri/LCA solutions. This case shows how challenges in industrial production can be transformed into concrete efficiency gains through automation with Karakuri/LCA.

Industry solutions

Pharmaceutical and medical technology

In pharmaceutical and medical technology, the highest cleanroom standards, GMP, FDA and ISO conformity as well as flexible and safe production environments are crucial. item offers a comprehensive product portfolio with over 4.500 components. This allows you to implement customized solutions for a wide range of processes - perfectly tailored to your requirements.

Optical industry

From the design of optical systems and components to raw material preparation, assembly and quality control: the item Building Kit System enables you to implement individual solutions for every production process. Thanks to their complete modularity, all item component solutions can be adapted to changing conditions at any time.