The project at a glance

Sectors and item topic areas

✓ Mechanical and plant engineering

✓ Automated production

✓ Integration of collaborative robotics

item components and solutions

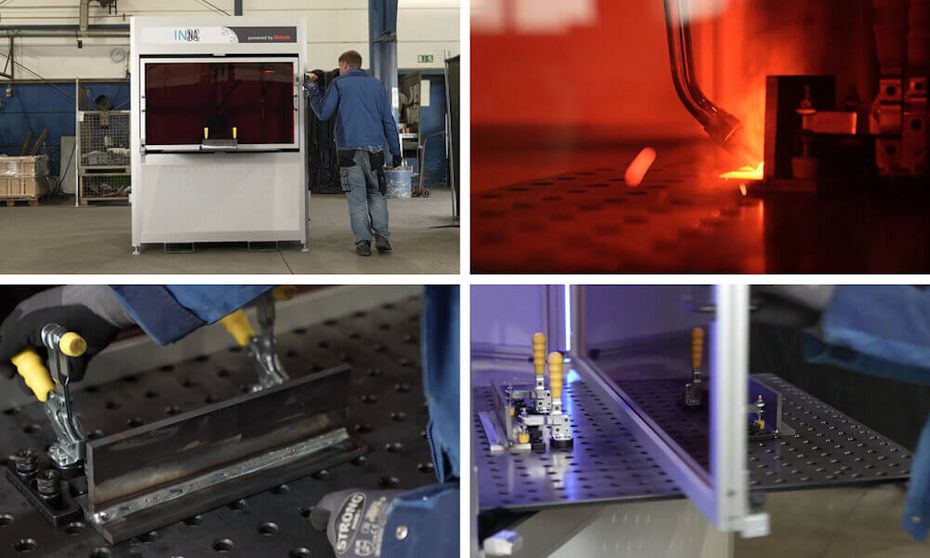

✓ Profile technology from Line XMS

✓ Modular machine cabins

✓ Integrated cable routing

✓ Rotating table

✓ Clamp fixtures for workpieces

Benefits

✓ Excellent repeatability and consistent quality

✓ Quick-start in automation

✓ Reduced set-up times thanks to rotating table

✓ Freeing up specialists from repetitive tasks

About INperfektion und Niederrhein Automation

INperfektion GmbH, based in Wegberg in Germany, is an item pluspartner that focuses on bespoke automation solutions for SMEs. Niederrhein Automation GmbH, which also operates out of Wegberg, specialises in collaborative robotics. Together with item, they developed the INNA robot cell to make automation economically viable for smaller companies – companies such as DAST Schweißtechnik GmbH.