Customized solutions for pharmaceutical and medical technology

In pharmaceutical and medical technology, the highest cleanroom standards, GMP, FDA and ISO conformity as well as flexible and safe production environments are crucial. To this end, item offers a comprehensive product portfolio with over 4.500 mutually compatible .components This allows you to implement customized solutions for a wide range of processes in pharmaceutical production and medical technology - perfectly tailored to your requirements.

That's why item is the ideal partner for your requirements

Solutions from item meet the highest standards of hygiene, safety, quality and flexibility. Whether cleanroom furniture and transport trolleys or ESD-safe workstations: Together with you, we develop individual applications that are precisely tailored to your requirements. Thanks to the modular system, you can adapt your item solutions to new production processes at any time. This lets you react quickly to new challenges.

Suitable for cleanrooms

When equipping cleanrooms, equipment must meet cleanroom classes, be easy to clean and must not release any particles. To this end, item offers the easy-to-clean XMS profiles with closed grooves, specially developed products for cleanrooms and silicone-free and chemical-resistant solutions. How to build workstations for a cleanroom laboratory as well as mini-environments, walk-in cleanrooms or doors for personnel and material airlocks in the cleanroom.

ESD-safe

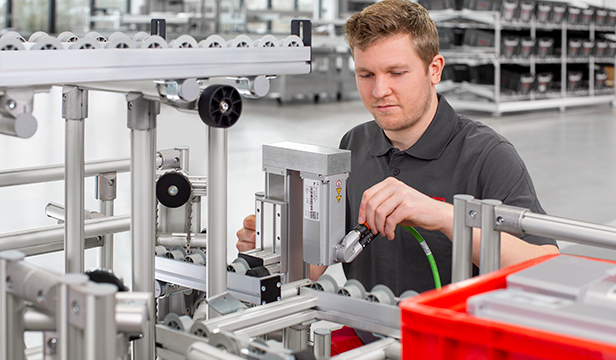

ESD protection is essential, especially in medical technology. To this end, item offers a wide range of ESD-safe solutions - from ESD workstations and other accessories such as ESD earthing terminals and ESD drag chains to dissipative conveyor and roller belts. How to protect electro-sensitive components from electrostatic discharge in every process step. Every ESD table is measured and recorded. You will receive the test report when you purchase your ESD work table.

Modular, scalable, made to measure

The item Building Kit System is ideal for responding quickly to changing production requirements and new products. Thanks to their modularity, the solutions enable rapid expansion or redesign of existing production lines in pharmaceutical and medical technology. They are scalable so that increasing production capacities can be served quickly. This is a great advantage, especially in times of crisis.

GMP-, FDA- and ISO-compatible

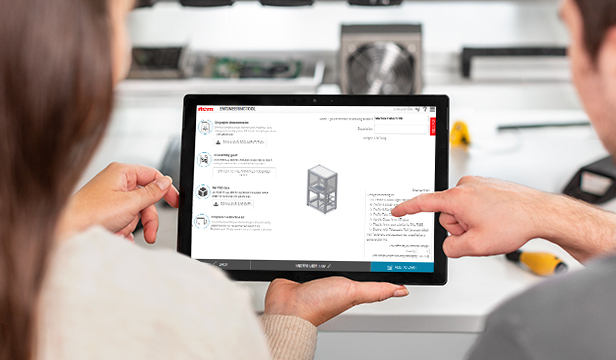

High levels of hygiene, product safety and traceability are essential to ensure that your equipment meets the relevant GMP, FDA and ISO standards. This requires complete documentation, regular inspections and the validation of every piece of equipment. The item Engineering Tool automatically creates comprehensive parts lists and other documents for each design, which facilitate documentation. In addition, our durable profiles and low-maintenance connection technology allow you to easily implement standard-compliant and future-proof solutions.

Ergonomic

Employee health and safety play a particularly important roller in the pharmaceutical and medical technology industries. Products such as height-adjustable tables, swivel arms and adjustable lighting reduce physical strain and increase productivity. If cobots or transport solutions are used for relief, standard-compliant safety fences and machine cabins ensure the protection of people and equipment.

Fast, reliable, supportive

item is more than just a supplier. We are your partner who works with you to ensure your success. We are at your side for the long term and support you with challenges, change requests and regular maintenance, for example. We also offer online training courses at the item Academy on topics such as cleanroom planning, ergonomic workbench design and machine safety. Alternatively, you can also attend one of our face-to-face training courses.

Frequently asked questions

With cleanroom solutions from item, you can achieve the highest cleanroom classes, such as ISO Class 1 and GMP Class A, depending on the application.

Thanks to their small edge radius and closed outer surfaces, the item profiles in Series X and XMS are suitable for most cleanroom solutions and easy-to-clean machine frames as part of cleanroom technology. The profiles are anodized. As a result, the surface does not corrode and is highly resistant to chemicals.

At item, we combine modular solutions with technical expertise and a deep understanding of the challenges in pharmaceutical production. This makes us your perfect partner.

With products from item, you can implement cleanroom-compatible solutions that are GMP, FDA and ISO-compliant and meet the highest standards of cleanliness, safety and flexibility. From cleanroom technology to the automation of pharmaceutical production - thanks to the full compatibility of the item product portfolio, production environments can be planned individually.

You can quickly adapt equipment as required and combined with ESD protection the item Engineering Tool makes planning easier for you and provides you with comprehensive documentation.

ESD protection plays a particularly important role in medical technology, as vital devices such as pacemakers and heart-lung machines are manufactured and repaired here.

Electrostatic discharge jeopardizes the functionality of these devices. To protect electro-sensitive components, item therefore offers ESD-safe workstations and a wide range of accessories, including ESD table mats, ESD earthing boxes, ESD drag chains and ESD-safe conveyor and roller belts. This allows you to build ESD-safe workstations, transport trolleys, FIFO racks or conveyor belts - even for clean production.

When you purchase an ESD-safe work table, you will receive a special ESD protocol. This proves that your work table has been checked at the relevant measuring points.

Thanks to its modularity, item's modular principle enables the adaptability and scalability of production processes.

With over 4,500 compatible components, you can build flexible and customized solutions for pharmaceutical production and medical .technology All solutions can be adapted to changing requirements or new production lines quickly and without long downtimes. Durch die Kompatibilität können Sie bestehende Betriebsmittel und Anlagen einfach erweitern oder umbauen, z.B. bei steigender Produktionskapazität.

With item, you can build a variety of cleanroom workstations, cleanroom furniture such as shelving and transport trolleys, as well as mobile cleanrooms with a partial enclosure or versatile Laminar Flow Box.

You can also use item components to design walk-in cleanrooms or machine cabins. The X and XMS series profiles are suitable for these applications. Thanks to their closed grooves and smooth surfaces, they are easy to clean and minimize particle formation.

The cleanroom furniture can be combined with ESD-safe components if required. With special seals and door locks, you can create doors for personnel and machine interlocks in cleanrooms, for example.

The solutions from item support the validation of processes in accordance with GMP and ISO standards through precise planning, the use of high-quality materials, comprehensive documentation and a network of specialized partners.

With the item Engineering Tool, you can easily design structures that are guaranteed to comply with the relevant standards. The configurator automatically creates complete documentation consisting of parts lists, assembly instructions and CAD data. This facilitates traceability and ensures compliance with regulatory requirements. When setting up your cleanroom solution, you can rely on our large network of specialized partners.

For automation in the pharmaceutical industry, item offers you a wide range of solutions such as conveyor belts and precision linear technology. In addition, item profile technology can be used to create flexible peripherals for integrating cobots and mobile robots.

This optimizes material flows and reduces manual intervention. You can integrate our solutions seamlessly into your control systems. In this way, item is helping to increase efficiency and safety in pharmaceutical production.