New in the item Engineeringtool

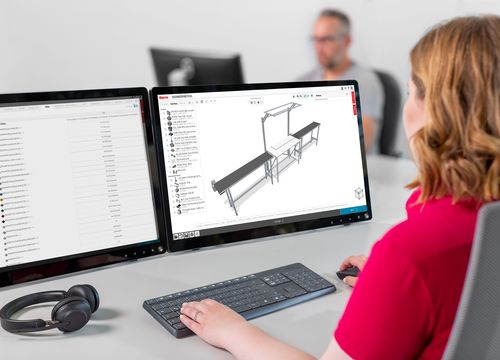

Designed and ordered in next to no time: The item Engineeringtool now gives users the option to create their own custom conveyor lines. Thanks to the use of predefined assemblies, it takes just a few clicks to put together bespoke transport solutions, while rules-based software and clear visualisations provide optimum user support. The online tool offers maximum design flexibility and ensures solutions can be quickly adapted to changing circumstances.

Getting goods from A to B: When using the item Conveyor Belt System, materials can be taken where they’re needed safely and reliably. The system’s modular design principle ensures conveyor sections can be operated independently, and can be easily integrated into pre-existing systems and facilities, too. Meanwhile, the item Engineeringtool gives users a rapid and simple means of planning conveyor belts and lines. Depending on the goods that need to be moved, users specify whether they want to design a system with a single or dual direct drive.

Error-free engineering for stable conveyor belt systems

The specialist software of the tool gives users invaluable support when configuring solutions. Users start by specifying the conveyor type and the desired properties. To ensure the construction always exhibits maximum stability, the tool automatically integrates cross profiles to suit the overall width. Conveyor belt support, which prevents sagging, is also added automatically. If required, users can integrate additional conveyor belt support at any time they like. Working within a user-friendly mask, users stipulate the conveyor type, set the system’s overall width, select the belt type (accumulating or non-accumulating) and enter the axle spacing and position of the motor. When it comes to choosing a drive unit, users can opt for various efficiency classes and transmission ratios. All they then need to do is use their cursor to drag the drive unit close to the conveyor belt and the system will immediately find the corresponding interface and add in the necessary motor fastening sets. Once the drive and conveyor belt have been connected together, the transport speed and the alignment of the motor can be specified. The stand structure is easy to select and position in the working area. Key parameters such as overall width, height, type of floor element and design need to be entered. Afterwards, the completed conveyor belt system can be ordered directly. As in the case of all projects, the Engineeringtool provides comprehensive project documentation, including an assembly guide. CAD data can be downloaded in the relevant file format in just a few minutes and then integrated into an in-house system. All this leads to a considerable time saving across the entire engineering process. Ultimately, the rules-based design system makes it possible to configure custom conveyor lines quickly, intuitively, and without any errors.

Length: 3,005 characters including spaces

Date: 10 July 2023

Photos: 2 (source: item)

Caption 1: The item Engineeringtool now gives users the option of creating their own custom conveyor lines based on predefined assemblies.

Caption 2: Flat belt conveyors, timing belt conveyors, single design, double design – this online software offers maximum flexibility for the design process and ensures solutions can be rapidly adapted to changing circumstances.