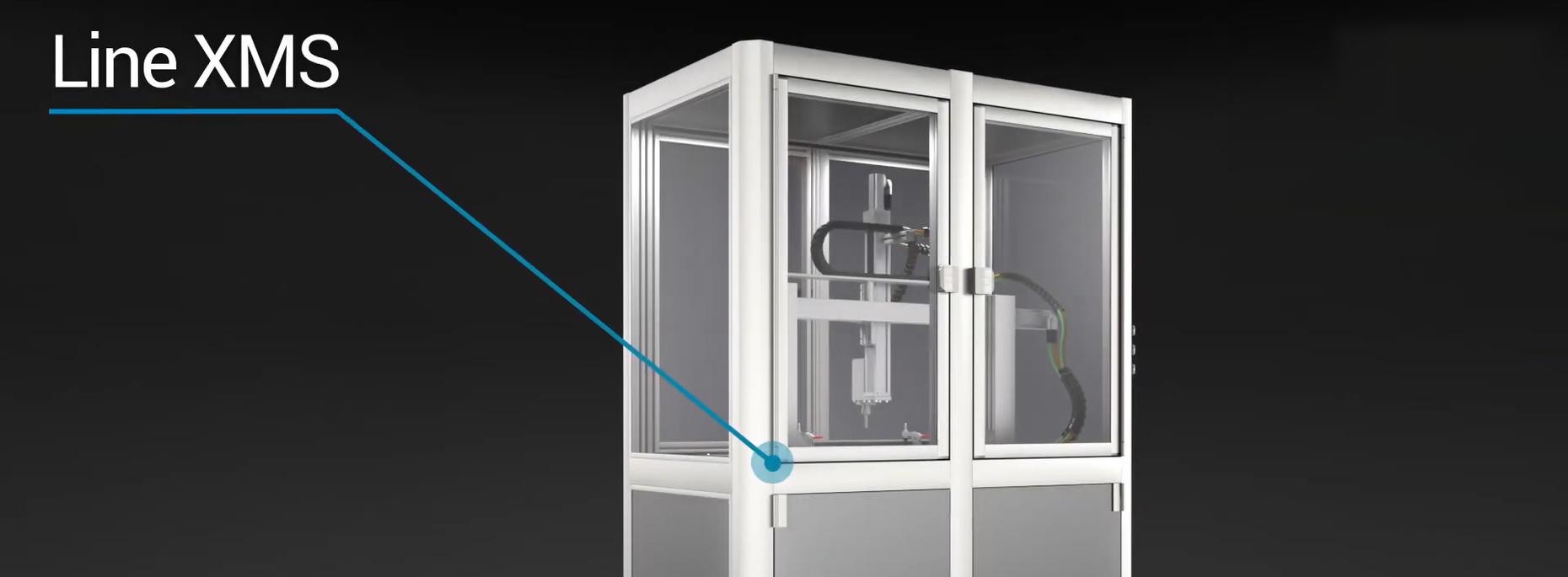

The advantages at a glance

Achieve the perfect machine frame with just a few components – only Line XMS can do it! The high-performance machine modules offer everything that state-of-the-art mechanical engineering requires. Utilising functions such as integrated cable conduits and special seal grooves, you can build highly functional machine cabins with ease. The Line XMS system is compatible with the world of the MB Building Kit System.

Winner of the “German Design Award 2014”!

In 2014, the German Design Council deliberated over a total of 1,900 entries to select the best 100 products from ten categories, and chose Line XMS from item.

Winner of the "iF product design award"!

Line XMS also won the international “iF product design award 2013”.