- Fast, manoeuvrable and always where it’s needed – with this stable frame, you can use even large cobots in different places. The central column offers a base area of 200x200 mm for attaching a cobot using item Robot Mounting Plate 8. Once the mobile cobot is where it needs to be, Jacking Castors make sure it stays securely in place. The integrated height adjustment levels out uneven floors.

Integrate cobots – with aluminium profile technology from item

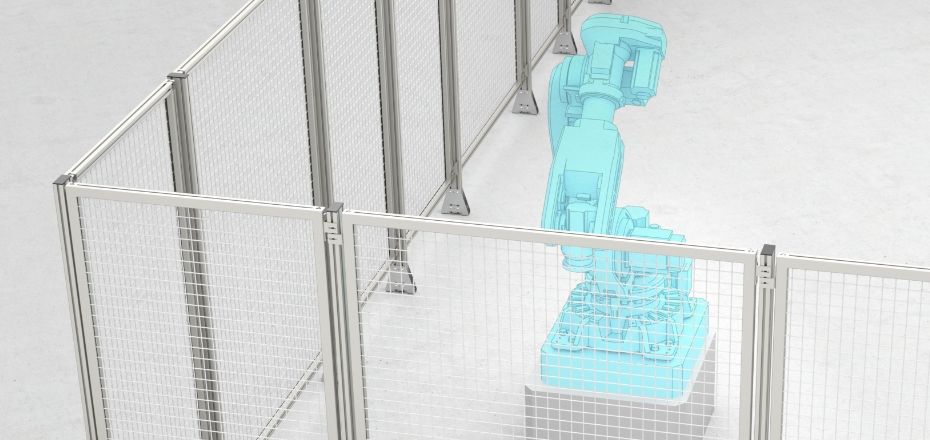

Robot cells, robot bases, robot tables and more.

Whether you’re using cobots for human-robot collaboration or to autonomously manufacture the smallest of batches, item ensures you can integrate lightweight robots safely and flexibly into your production operations. Options range from mobile robot cells and modular robot bases to extendible robot tables and more. Use our standard solutions as they are, customise them to your needs or design your own solution from scratch based on our tried-and-tested aluminium profile technology.