Today’s production and logistics environments are changing rapidly. Workflows are becoming more incremental and material flows more dynamic. As part of its response to these challenges, item is exhibiting Release Unit DIN/DOUT 24V – its new material flow automation solution – at LogiMAT 2026.

Combining stationary and mobile process operations to optimum effect, the new Release Unit DIN/DOUT 24V from item is a smart component for shooter and sorting processes. This solution replaces conventional mechanical stoppers and makes workflows autonomous, without any external controller being required. The Release Unit combines electromechanical functions with intelligent sensor technology and integrated logic components. This opens up a whole host of possible applications. For example, the unit can be used as a shooter, controlling the release of small load carriers (SLCs) to ensure transfers take place as specified. When it comes to sorting, the unit can selectively release individual SLCs. Two units installed one behind the other can control the sorting process independently – on infeed sections upstream of production systems or upstream of SLC lifts, for instance. If longer distances are involved, a third unit can be added to distribute loads and reduce back pressure. The new solution configures itself the first time it is taken into operation, automatically adapting to the number of units connected. Customising the logic operation via a web interface is then easy using a QR code.

Smart FIFO rack

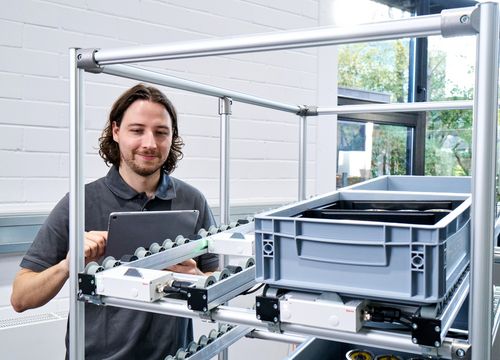

At LogiMAT, item is also using the example of a material distribution station to demonstrate the features of an automated material flow. This application shows how mobile robotics, the Lean Production Building Kit System and smart products interact to create an end-to-end workflow – from the material supply stage all the way through to manual removal. The solution is centred around a FIFO rack equipped with pick by light signalling. A mobile industrial robot system with an item Top Module brings SLCs to the rack and positions itself at the relevant transfer station, where the Release Units take care of transfer to free storage locations on the rack in a well-ordered, automated operation. The picking process then starts, with the LED Strips at the removal end guiding operators step by step through the removal stage – a transparent, intuitive workflow featuring excellent operational reliability. item innovations this spring include a pick by light mode for LED Strip Controller DIN/AIN. Making picking applications easy without an additional controller, this extends the potential uses of signalling solutions. The basic functions can be configured quickly via the web interface to activate specific segments of the LED Strip.

Visitors to Stand 5B21 at LogiMAT will get a taster of upcoming useful additions to the portfolio of smart products. Other exhibits being showcased by item cover the areas of static robotics, mobile robotics, conveyor belt systems and work bench solutions.

As at: 13 January 2025

Length: 3153 characters including spaces

Photos: 3 (© item)

Captions

Figure 1 The new Release Unit DIN/DOUT 24V from item is a smart component for shooter and sorting processes that combines stationary and mobile process operations to optimum effect.

Figure 2 The Release Unit replaces conventional mechanical stoppers and makes workflows autonomous, without any external controller being required.

Figure 3 item signalling solutions can be used in an ever-increasing number of ways. For example, pick-by-light applications are now also possible.